The Hidden Value Driver in Your Organization

When manufacturing equipment fails unexpectedly, the costs cascade rapidly. Production lines halt. Workers stand idle. Orders delay. Customer satisfaction plummets.

This scenario plays out daily across global industries, with unplanned downtime costing manufacturers an estimated $50 billion annually according to Aberdeen Research. At the heart of preventing these disruptions lies an often-overlooked function: MRO procurement.

Maintenance, Repair, and Operations (MRO) procurement encompasses all the parts, supplies, and services needed to keep facilities and equipment running efficiently. While seemingly mundane, MRO typically represents 15-25% of an organization’s indirect spend, according to The Hackett Group’s 2022 Procurement Benchmark.

This article explores how leading organizations are transforming their approach to MRO procurement—moving from reactive purchasing to strategic value creation—and how intelligent technology is enabling this evolution.

MRO by the Numbers: The Scale of the Opportunity

Before examining transformation strategies, let’s understand the economic significance of MRO procurement:

- Financial Impact: According to a study by Deloitte, effective MRO management can reduce overall maintenance costs by 10-15% annually.

- Operational Impact: Research from McKinsey reveals that best-in-class MRO management can reduce machine downtime by up to 30-50%.

- Inventory Efficiency: The ARC Advisory Group found that organizations typically have 25-30% excess MRO inventory, representing millions in tied-up working capital.

- Process Complexity: A typical manufacturer maintains 25,000-50,000 MRO SKUs and manages hundreds of suppliers, according to IDC Manufacturing Insights.

- Compliance Challenges: Studies from Supply & Demand Chain Executive show that up to 40% of MRO purchases happen outside established procurement channels.

The management complexity and financial opportunity make MRO procurement a prime target for strategic transformation.

Read more: Smart Intake Management for MRO Procurement: Hours, Not Weeks

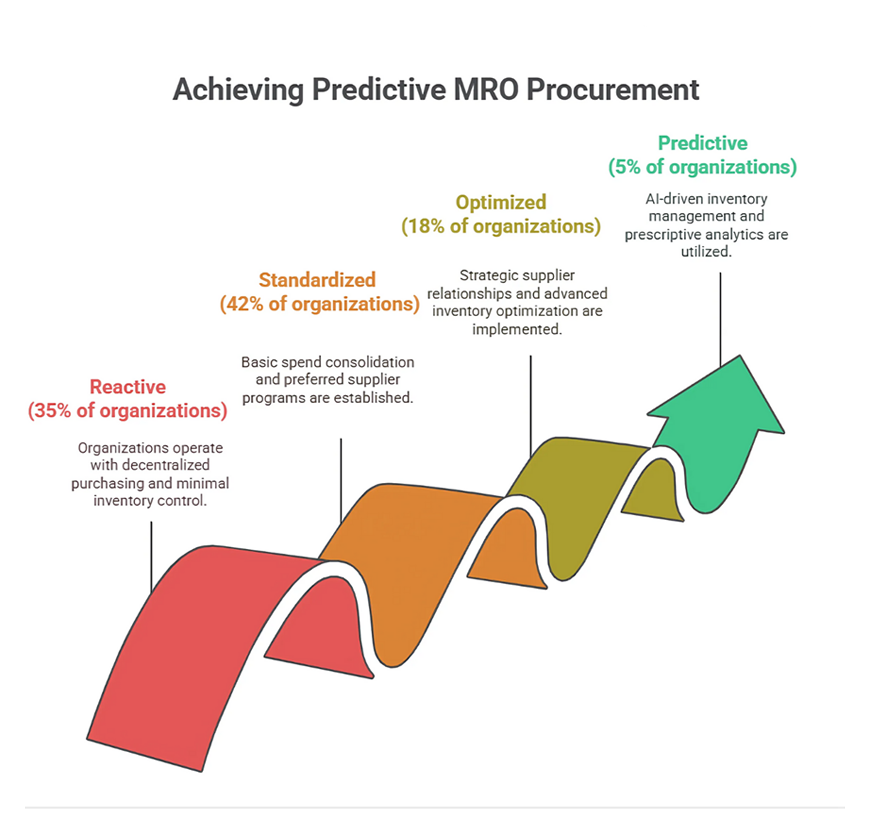

The MRO Maturity Journey: From Reactive to Predictive

Organizations typically evolve through several stages of MRO procurement maturity:

Stage 1: Reactive (35% of organizations)

- Decentralized purchasing

- Minimal inventory control

- Emergency buying as standard practice

- No visibility into total MRO spend

Stage 2: Standardized (42% of organizations)

- Basic spend consolidation

- Preferred supplier programs

- Simple inventory management

- Limited data analysis

Stage 3: Optimized (18% of organizations)

- Category management approach

- Strategic supplier relationships

- Advanced inventory optimization

- Spend analysis and compliance tracking

Stage 4: Predictive (5% of organizations)

- Integrated with maintenance systems

- Condition-based procurement

- AI-driven inventory management

- Prescriptive analytics and automation

According to research from The Hackett Group, organizations at Stage 4 maturity achieve 30-35% lower total cost of ownership for MRO categories compared to those at Stage 1.

Explore Zycus’s procurement maturity framework

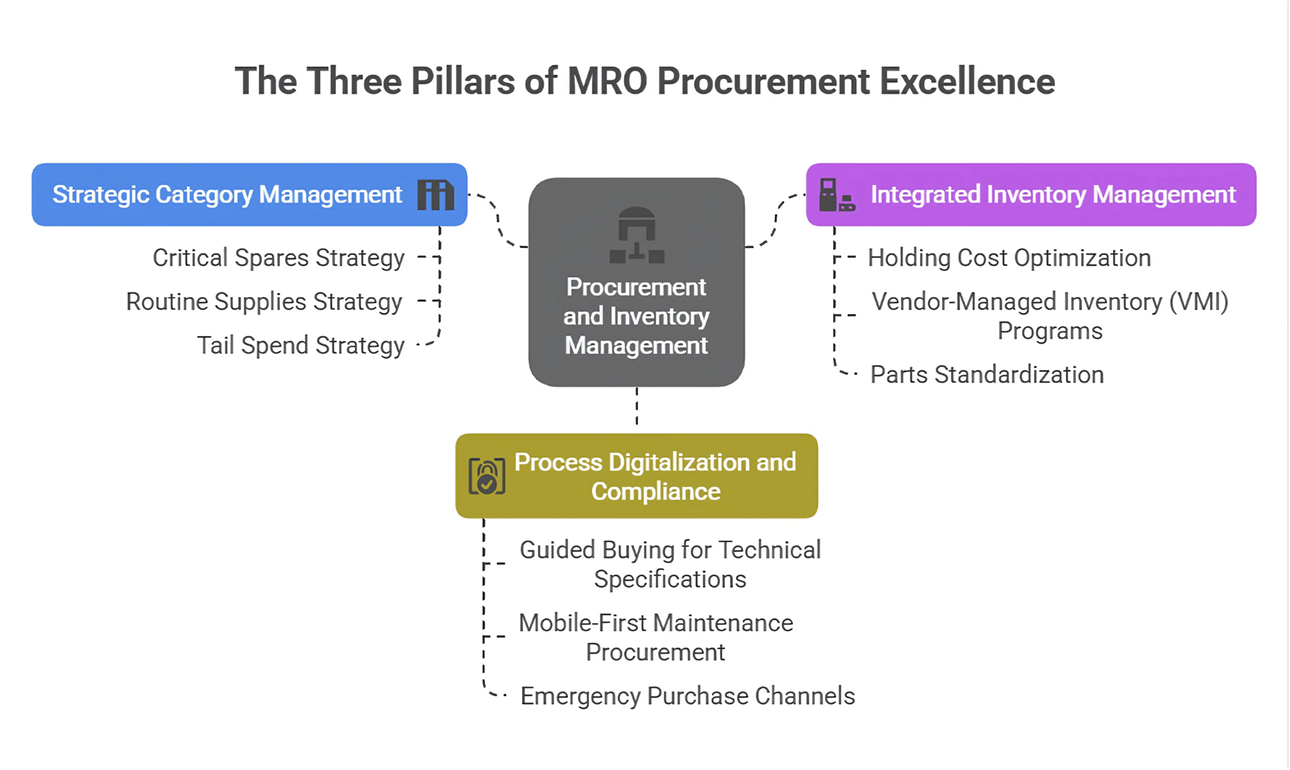

The Three Pillars of MRO Procurement Excellence

Leading organizations build their MRO procurement strategy around three core elements:

1. Strategic Category Management

Rather than treating all MRO items equally, progressive organizations segment their approach:

Critical Spares Strategy

- Represents 15-20% of MRO items but 60-70% of value

- Failure causes significant operational impact

- Requires strategic sourcing, supplier collaboration, and specialized storage

Routine Supplies Strategy

- Represents 30-40% of MRO items and 20-25% of value

- Regular usage patterns with multiple supplier options

- Best managed through catalogs and marketplaces

Tail Spend Strategy

- Represents 40-50% of MRO items but only 10-15% of value

- Thousands of low-value transactions

- Typically managed through spot buying or p-cards

According to a McKinsey analysis, this segmented approach typically yields 7-12% cost savings while significantly improving operational outcomes.

Discover Zycus’s strategic sourcing solution for MRO

2. Integrated Inventory Management

Effective MRO procurement requires tight integration with inventory management:

Holding Cost Optimization

The ARC Advisory Group estimates that effective MRO inventory management can reduce carrying costs by 25-30% while increasing service levels. This requires:

- Scientific minimum/maximum levels based on criticality

- Multi-echelon inventory models for complex operations

- Regular obsolescence reviews (15-20% of MRO inventory typically obsolete)

Vendor-Managed Inventory (VMI) Programs

According to a study by Supply Chain Management Review, well-implemented VMI programs for MRO can:

- Reduce stockouts by 60-80%

- Lower inventory carrying costs by 25-30%

- Decrease procurement process costs by 45-55%

Parts Standardization Research from ProcureCon Indirect shows organizations with formal standardization programs have 30-40% fewer MRO SKUs, significantly reducing costs and complexity.

Explore Zycus’s supplier management solution for VMI programs

3. Process Digitalization and Compliance

The third pillar addresses the process challenges of MRO procurement:

Guided Buying for Technical Specifications

A study by The Hackett Group found that guided buying platforms reduce off-contract spending by 25-35% for technical categories like MRO.

Mobile-First Maintenance Procurement

IDC Manufacturing research shows that mobile procurement solutions for maintenance technicians can reduce procurement cycle times by 60-70% while improving compliance by 40-50%.

Emergency Purchase Channels

Research from APQC indicates that organizations with structured emergency procurement processes reduce the cost premium on urgent purchases by 15-25% compared to those without such processes.

Discover Zycus’s procure-to-pay solution for MRO

The Transformation in Action: Three Case Studies

Global Pharmaceutical Manufacturer

Challenge:

Operating 14 production facilities globally, this organization struggled with fragmented MRO procurement, excessive inventory ($42M across sites), frequent stockouts, and high emergency purchase premiums.

Approach:

- Implemented category management for strategic MRO items

- Deployed integrated procurement-inventory platform

- Established VMI programs for critical maintenance items

- Developed mobile procurement capabilities for maintenance teams

Results:

- 17% reduction in total MRO costs ($7.2M annually)

- 32% decrease in maintenance-related downtime

- 29% reduction in MRO inventory value

- 85% improvement in procurement process compliance

Heavy Equipment Manufacturer

Challenge:

With operations across North America, this company faced challenges with parts standardization (76,000+ MRO SKUs), local buying practices, and limited spend visibility.

Approach:

- Created cross-functional team for MRO standardization

- Implemented AI-based parts classification and standardization

- Deployed enterprise-wide MRO catalog system

- Established formal VMI partnerships for repetitive items

Results:

- 27% reduction in total MRO SKUs

- 14% decrease in total MRO spend

- 46% faster procurement cycle times

- 22% improvement in first-time fix rates for maintenance

Energy Utility Provider

Challenge:

This utility struggled with geographically dispersed operations, emergency procurement needs during outages, and significant working capital tied up in MRO inventory.

Approach:

- Developed strategic regional stocking locations

- Implemented AI-driven inventory optimization

- Created specialized emergency procurement process

- Deployed mobile procurement solutions for field workers

Results:

- 35% reduction in emergency procurement premium

- 28% decrease in inventory carrying costs

- 62% faster response time during outage events

- 19% improvement in overall maintenance productivity

See more procurement transformation case studies

Key AI Technology Enablers Transforming MRO Procurement

The next generation of MRO procurement is being shaped by Artificial technological innovations:

1. AI-Powered Parts Identification

One of the most persistent challenges in MRO is accurately identifying the correct replacement parts. Advanced AI solutions now address this challenge:

- Computer vision systems can identify parts from images

- Natural language processing interprets technical descriptions

- Machine learning matches descriptions across supplier catalogs

ProcureTech research shows these technologies reduce incorrect parts ordering by 70-85% while accelerating identification by 5-10x.

2. Autonomous Procurement

Beyond simple automation, autonomous procurement uses Agentic AI to make actual purchasing decisions within defined parameters:

- Automatic reordering based on inventory thresholds

- Dynamically adjusting order quantities based on usage patterns

- Autonomous supplier selection based on performance analytics

Aberdeen Research reports that organizations implementing autonomous procurement for routine MRO items reduce procurement administration costs by 30-50%.

Explore Zycus’s autonomous procurement capabilities

Implementation Playbook: The Path to MRO Excellence

For organizations looking to transform their MRO procurement, the following roadmap provides a structured approach based on successful implementations:

Phase 1: Assessment & Visibility (Months 1-3)

Key Activities:

- Conduct comprehensive MRO spend analysis

- Create part criticality framework

- Assess inventory management practices

- Benchmark current state against industry standards

- Define opportunity areas and business case

Technology Focus:

- Spend analysis implementation

- Data cleansing and classification

- Inventory assessment tools

Learn about Zycus’s spend analysis capabilities

Phase 2: Foundation Building (Months 3-6)

Key Activities:

- Develop category strategies for key MRO segments

- Implement basic catalog management

- Establish preferred supplier program

- Create standardized procurement processes

- Develop emergency purchase protocols

Technology Focus:

- Catalog management system

- Basic inventory management

- Procurement workflow automation

Explore Zycus’s catalog management solution

Phase 3: Advanced Optimization (Months 6-12)

Key Activities:

- Implement VMI for critical items

- Deploy mobile solutions for technicians

- Establish cross-functional parts standardization

- Develop KPIs and performance management

- Initiate predictive maintenance program

Technology Focus:

- Supplier collaboration platform

- Mobile procurement applications

- Integration with maintenance systems

- Advanced analytics implementation

Discover Zycus’s supplier collaboration tools

Phase 4: Intelligent Transformation (Year 2)

Key Activities:

- Implement AI-driven parts identification

- Deploy condition-based procurement

- Establish autonomous purchasing for routine items

- Develop digital twin capabilities

- Create continuous improvement framework

Technology Focus:

- AI and machine learning capabilities

- IoT integration and analytics

- Autonomous procurement agents

- Digital twin modeling

Explore Zycus’s AI capabilities for procurement

Measuring Success: MRO Procurement KPIs

To track the success of MRO procurement transformation, organizations should monitor metrics across five dimensions:

1. Financial Performance

- Total MRO spend as percentage of asset value

- Cost savings (year-over-year)

- Emergency purchase premium percentage

- Cost of stock-outs (production impact)

2. Operational Efficiency

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

- Equipment availability percentage

- First-time fix rate

3. Inventory Optimization

- Inventory turns for MRO items

- Obsolete inventory percentage

- Service level achievement

- Working capital reduction

4. Process Effectiveness

- Procurement cycle time (regular vs. emergency)

- Compliance to procurement process

- Purchase order accuracy

- System adoption rates

5. Supplier Performance

- On-time delivery percentage

- Quality/defect rates

- Price competitiveness

- Innovation contribution

According to research from The Hackett Group, best-in-class MRO procurement organizations review these metrics monthly with cross-functional teams including maintenance, operations, and finance.

Learn about Zycus’s analytics and reporting capabilities

Conclusion: From Cost Center to Value Creator

As this exploration has shown, MRO procurement is evolving from a reactive, administrative function into a strategic driver of operational performance. Organizations that successfully transform their MRO procurement approach can expect:

- 10-15% reduction in total MRO costs

- 30-50% decrease in unplanned downtime

- 25-35% improvement in maintenance productivity

- 15-25% release of working capital from inventory

The journey requires coordinated effort across procurement, maintenance, operations, and IT functions—but the business case is compelling. As one manufacturing CEO noted in a recent ProcureCon survey:

“Our MRO transformation wasn’t just about saving money on parts; it fundamentally changed our operational reliability.”

In an era of supply chain disruption and increasing pressure on operational efficiency, strategic MRO procurement has become a competitive differentiator that directly impacts the bottom line.

Discover how autonomous procurement represents the new frontier in MRO management

Related Reads:

-

- Zycus Leads the Way with Agentic AI at ProcureCon Indirect West 2025

- 30-Day Guide to Implementing a Cost-Saving Indirect Procurement Strategy

- From Data to Decisions: How to Leverage AI for Smarter Sourcing

- 5 Key Benefits of Automating Tail Spend Management

- Why Mid-size Organizations Should Invest in Procurement Automation Now

- The Future of Sourcing: Autonomous Solutions for Procurement

- Beyond GenAI: The Dawn of Agentic AI

- Autonomous AI Negotiation Agents: Unlocking Millions from Missing Middle

- Artificial Intelligence use cases- Identifying and realizing the real value

- Solution: Generative AI Platform for Source to Pay Transformation

- Solution: GenAI-powered Procure to Pay Software