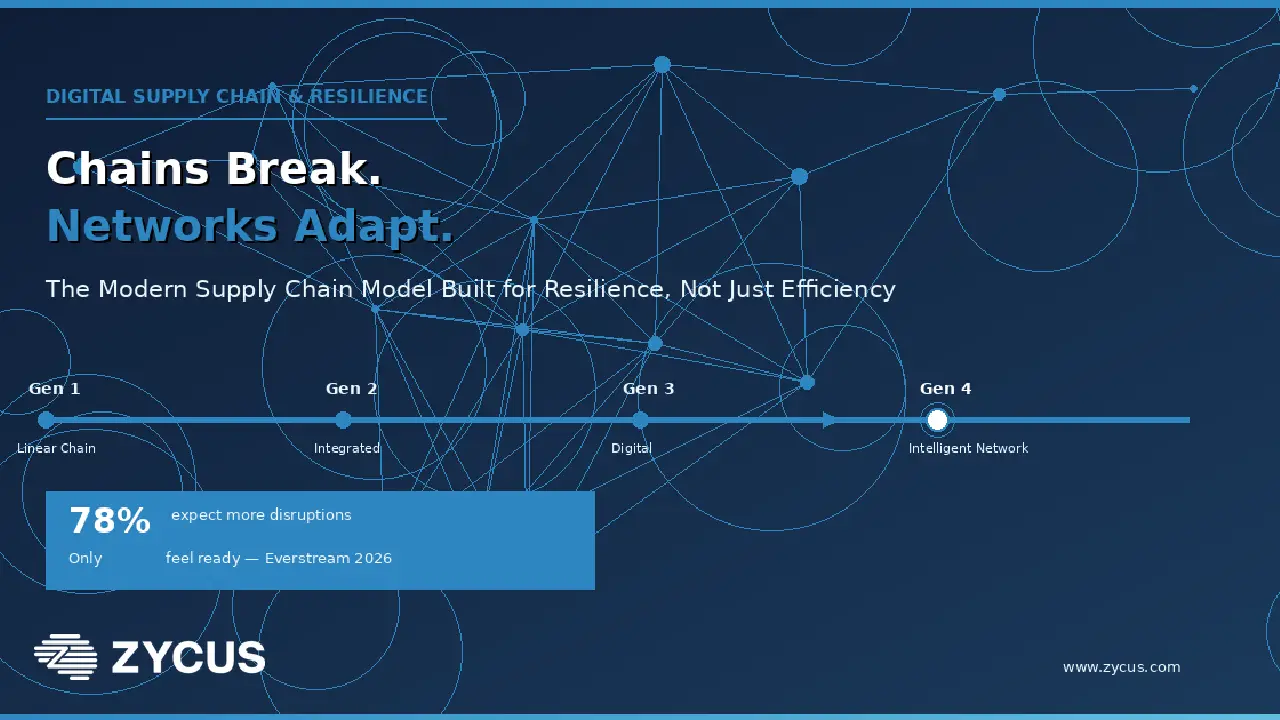

According to the latest Procurement Key Issues study by The Hackett Group, managing supplier risks is cited as the second most important concern for procurement in the next year. In addition, the report notes that the concept of supplier risk has broadened from one of supplier viability and continuity to an approach that includes supplier compliance with both regulatory and performance requirements.

In spite of this, most companies we observe still use only rudimentary models for capturing and mitigating supplier and supply-chain risks. These can be broadly classified into:

- Quantitative: collecting financial details, quality certifications and other important — but basic-level information

- Qualitative: related to historic performance parameters such as on-time delivery, number of defective parts per million, adherence to discount rates and so forth.

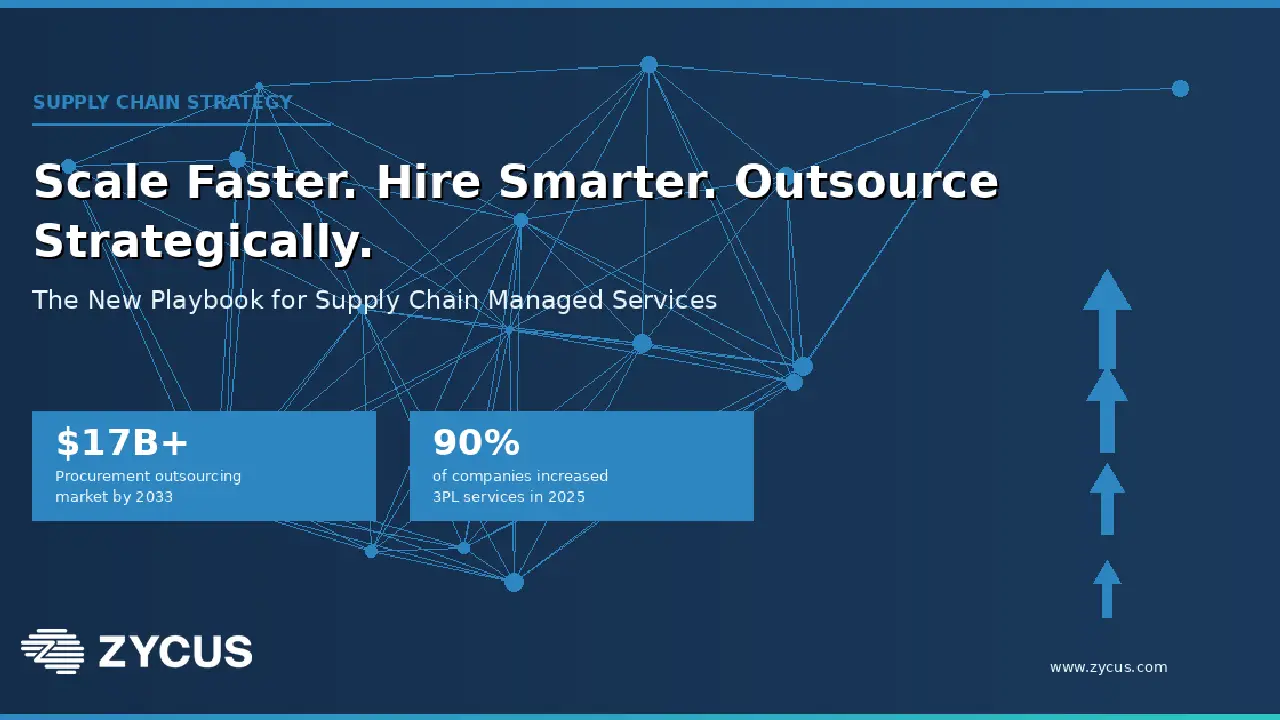

Building a sustainable supplier relationship requires organizations to consider suppliers’ entire ecosystem to managing supply risk & preventing costly supply disruptions. Such an approach requires analysis of suppliers’ markets, competitors, and the overall performance of their extended supply chains.

Best in class organizations are leveraging on the procurement automation solutions to build sustainable supplier relationships. This post will provide a brief insight into the role played by Supplier Information Management (SIM) & Supplier Performance Management solutions (SPM) in building a better relationship with suppliers.

SIM solutions acts as a central repository for all supplier information including legal details, quality certifications, numbers of employees, business regulatory permissions, compliance certificates, corporate hierarchies, diversity status and so forth. Information gathered must provide 360-degree views of important suppliers. Integrated supplier blacklist lookups ensure that a company does not engage in business with debarred parties.

SPM monitors suppliers on Key Performance Indicators (KPIs) set by the organization. These vary across organizations, verticals and geographic regions. KPIs should essentially represent a mixture of qualitative and quantitative information captured in the SIM module. Configurable supplier scorecards can be based on combined qualitative and quantitative performance metrics.

Learn More: Vendor Management Guide

Related Read:

- Blog – How to Effectively Mitigate Supply Chain Risk in the Manufacturing Sector

- Blog – An Overview of S2P KPIs, The Balancing Act & Benchmarks

- Blog – Vendor Landscape: Supplier Risk And Performance Management

- Zycus’ iSupplier, Supplier Information Management Software

- White paper – Ensuring Efficient Supplier Risk Management with Supply Chain Transparency

- TechWatch: Transform Supplier Risk Management with iRisk