The last two years have been turbulent for the manufacturing industry. Broken supply chains, unavailability of heavy goods vehicle (HGV) drivers, and production stoppages had a negative impact. 2022 is no way better; it has begun with semiconductor manufacturers facing chip shortages. And the war in Europe has only aggravated the situation.

Disruption has indeed become the new normal. It made several manufacturers realize the need to focus on how to Mitigate Supply Chain Risk through strategies to re-imagine their supply chains.

Supply Chain Risk Assessment – Ground Reality

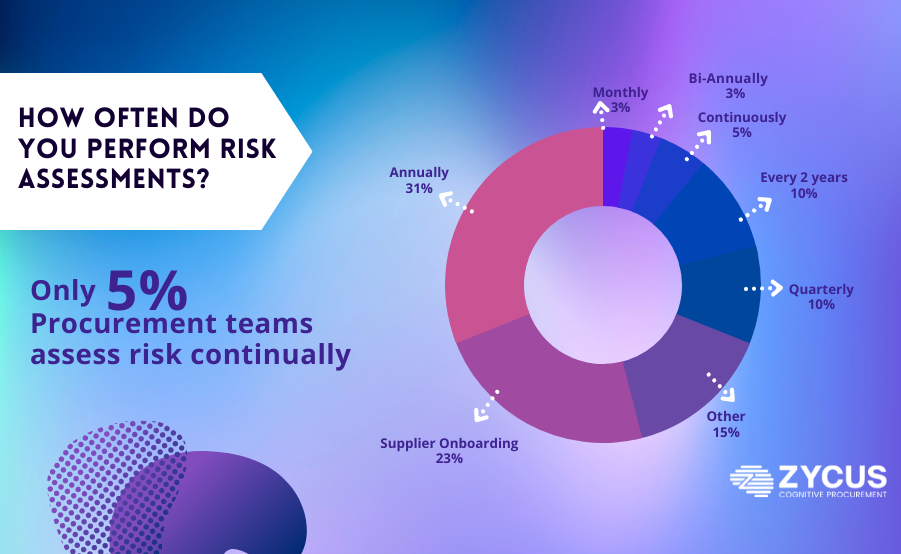

In our recently concluded webinar – Superheroes of Procurement: Acquiring and Accessing Procurement’s Superpowers – in association with SIG, we ran a poll with regards to supplier risk assessments, 23% of procurement leaders mentioned that they conduct risk assessments only when a supplier is onboarded and another 10% voted for every two years. This revealed that at least one-third of the organizations are not focusing on supplier risk.

In the early part of this year, The Hackett Group released their 2022 Procurement Key Issues Study. According to their findings, only 20% of organizations continuously monitor risk activity. This is a major concern, especially in the manufacturing domain, where risk management has detrimental effects on their end customers.

Read more: AI for Supply Chain Risk Intelligence: A Game Changer for Resilient Supply Chains

Need for Supply Chain Risk

A typical supply chain today includes multiple partners spread across numerous organizations and geographies. Third-party relationships have a much more profound and far-reaching impact on the strategy, operations, and reputation of an organization. The number of third parties a large manufacturing organization works with can run into hundreds or even more, leading to a web of complex relationships.

Therefore, as the business expands, understanding what are the supply chain risks and combating supplier risks, along with monitoring their performance against contract requirements, becomes indispensable.

Download our whitepaper: How prepared are you to combat your supply chain risks?

Supplier Risk Management Approach for Manufacturing Firms –

Following are the steps to build a structured approach for supplier risk management:-

- Identification of current and potential risk sources using technologies like AI

- Assessment and prioritization of risks in terms of probability and impact based on clean data

- Ensuring suppliers meet the performance criteria, e.g. service and quality levels agreed upon in the contract

- A comprehensive view of supplier risk profiles

- Identification of room for improvement and initiation of corrective actions

- Supplier diversification

- Periodic review of risks and analysis changes if any

Read more: Top 10 Supplier Risk Management Best Practices For Procurement Professionals

Practical steps to mitigate supply chain risk

Let us go through some critical steps that will help in establishing a robust supply chain risk management structure for your manufacturing firms

1) Investing in Supply Chain Software

In the digital age, managing supply chain risks, regardless of industry, calls for AI-powered advanced analytics that complements human ingenuity. Supply chain risk management software needs to be transparent and decentralize to ensure that you get the optimum performance from your suppliers.

Zycus’ risk management module iRisk measures supplier performance by setting performance yardsticks and evaluating suppliers against those benchmarks. It also empowers the team by collaborating with suppliers for creating –Supplier Development Programs – enabling suppliers to enhance their overall performance and ensure consistency. It also ensures simplified data analysis that can help in building models, contingency plans, and process improvement strategies.

2) Proactive Supplier Risk Management

To mitigate what are the supply chain risks in manufacturing, firms need to have complete visibility of the risks around all of their suppliers. Risk assessment should be conducted at regular intervals to identify and eliminate any kind of risk exposure. Procurement functions must have a dedicated cross-functional risk team to focus on external supply chain assessments and relationship management strategy conducted by a focused cross-function risk management team.

Zycus’ iRisk solution helps in designing a supplier development program to carve out strategies for improvements. This program empowers teams by developing redundancies and minimizing any kind of supply chain blockages.

Download our whitepaper: Supplier Risk Management Framework: A Comprehensive Approach to Mitigating Supplier Risks

3.) Developing and Prioritizing Business Continuity Plan

To mitigate supply chain risk effectively manufacturing organizations must focus on prevention. The primary objective of a business continuity plan is to protect and maintain the smooth running of the company’s operations during a supply chain disruption.

This requires a detailed risk assessment. Following is an approach that highlights the PPRR model of identifying all kinds of risks and their purpose.

- Prevention – measures helpful for reducing as well as eliminating risk exposure

- Preparedness –To establish the most appropriate and time-sensitive responses

- Response – Taking actionable measures to control, limit, and minimize the impact of the disruption

- Recovery – Taking necessary measures to overcome disruptions quickly and safely

4.) Navigating Cyber Risk

As supply chains increasingly are using modern technologies for business processes, cyber risks are going to be one of the most critical areas of supplier risk management. In today’s uncertain times, these can cause massive disruptions. Some of the steps that can be taken to mitigate these include-

- Defining user roles and providing role-based access to the system

- Setting a compliance benchmark for all third-party vendors

- Conducting detailed vendor risk assessment before contract signing

- Having a disaster recovery plan in place

- Updating the firewall system of the organization’s system at regular intervals

5.) Model Risk Event Scenarios

Zycus’ Merlin AI helps manufacturing firms in monitoring 360-degree risks across millions of internal and external resources and enables risk assessments. Its ability to create potential scenarios with the help of predictive analytics and data modeling provides a close enough picture to take action.

Accessibility of such intelligent risk models plays a critical role in identifying gaps, thereby resulting in developing contingency plans to recover from any disaster.

6.) Environment Risk

The pandemic exposed big gaps in the global supply chain network of manufacturing organizations. Having said that there is no definitive way to prepare for certain environmental risks, however, risk teams devise a business continuity plan to make sure the lights are on.

Some of the fundamental strategies that you can apply for managing environmental risks include:

- Multisource – Suppliers should be categorized not only based on costs but also based on the impact of disruption. The smart approach would be to identify suppliers that work out of multiple locations. Zycus’ Supplier Network Portal can precisely help in this process and provide a comprehensive analysis of the best possible vendors.

- Nearshore – Manufacturing organizations should identify suppliers close to their operations center to lower the lead time for delivery as well as product development. Sometimes partnering with regional suppliers can be expensive, but when it comes to avoiding any kind of potential risks it is a much better approach.

Zycus Case Study

Similarly, Abdul Latif Jameel Motors Saudi Arabia utilized Zycus’s Source to Pay software to rationalize their procurement lifecycle through automated processes. This integration not only improved procurement efficiency but also decreased supplier setup time by 30%, illustrating a practical approach to enhancing visibility and mitigating risks associated with supplier management. The use of digital tools like these helps establish a robust framework for preemptive supplier risk assessment, which is essential for manufacturing firms navigating today’s complex supply chain landscape.

Conclusion

Supply risk management in the manufacturing industry is one of the topmost areas of concern. It is absolutely critical for firms to devise and develop robust programs for both known and unknown global supply chain issues. Having an effective supply chain risk mitigation strategy is not just a set governance issue, but a company-wide mindset change that requires adequate investment.

Zycus supplier management software emphasizes strict regulatory control and compliance. It enables increased stakeholder participation, transparency in performance metrics, and reinforces credibility in management processes. It results in better identification of supplier-related risks and helps in making informed decisions.

Schedule a demo to learn more about how our AI-powered supplier risk management solutions can help you transform your supplier risk management practices and build a more resilient supply chain.

FAQs

Q1. What role does diversification play in mitigating supply chain risk?

Diversification helps reduce dependency on a single supplier or geographical region, thus minimizing the risk of disruptions.

Q2. How can technology aid in supply chain risk management in manufacturing?

Implementing advanced technologies like AI and IoT provides real-time data and predictive analytics to foresee and manage potential risks effectively.

Q3. Why is supplier relationship management crucial for mitigating supply chain risk?

Building strong relationships with suppliers ensures better communication, reliability, and collaborative problem-solving during disruptions.

Q4. What is the importance of inventory management in reducing supply chain risk?

Effective inventory management ensures buffer stock availability, reducing the impact of supply chain disruptions on production.

Q5. How does scenario planning assist in supply chain risk mitigation?

Scenario planning prepares the organization for potential disruptions by evaluating various ‘what-if’ situations and developing strategic responses.

Related Read:

- Supplier Management–Benefits, Process, & Best Practices

- How to Effectively Mitigate Supply Chain Risk in the Manufacturing Sector

- 5 procurement levers to optimize manufacturing supply chain during a pandemic

- White Paper: Ensuring Efficient Supplier Risk Management with Supply Chain Transparency

- White Paper: 5 Steps for effective supply chain management

- Whitepaper: Supplier Risk Management Framework: A Comprehensive Approach to Mitigating Supplier Risks

- Whitepaper: How prepared are you to combat your supply chain risks?

- Solution: Supplier Management Software

- Solution: End-to-End Supplier Risk Management Software Powered by GenAI