TL;DR

- Supplier Risk Management (SRM) is the process of identifying, assessing, monitoring, and mitigating risks across the supplier lifecycle.

- It protects supply chain continuity from financial, operational, geopolitical, ESG, and cybersecurity risks.

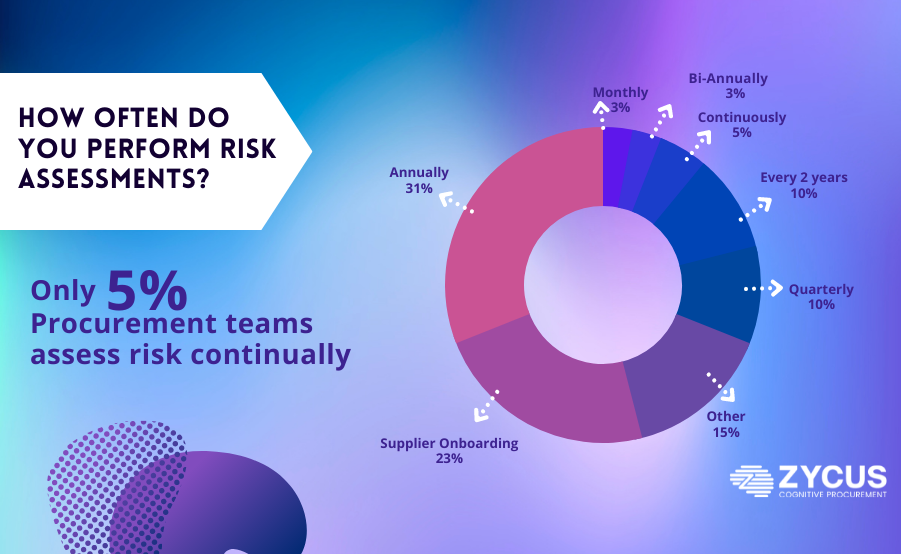

- Continuous risk monitoring is critical—supplier risk is not a one-time assessment.

- AI and third-party data enable real-time risk detection, predictive alerts, and faster mitigation.

- A structured Assess–Monitor–Mitigate approach builds resilience and competitive advantage.

- In 2026, proactive supplier risk management is essential for compliance, reputation, and business continuity.

What is Supplier Risk Management?

Supplier risk management is a critical component of supply chain management that focuses on identifying, assessing, and mitigating risks associated with suppliers. These risks can arise from various factors, including financial instability, geopolitical events, natural disasters, regulatory changes, and operational disruptions.

The primary objective of supplier risk management is to ensure the continuity and reliability of supply chains. This involves evaluating potential risks that could impact the supply chain, developing strategies to minimize these risks, and implementing contingency plans to address any disruptions that may occur.

How it is Difference from Enterprise Supplier Risk Management

As per Gartner’ glossary enterprise supplier risk management is the ability to assess and monitor supplier risk by tracking supplier financial performance, geopolitical risks, news sentiments, judicial filings and regulatory compliance.

Business continuity is becoming increasingly important, especially after series of events in past two years and excessive turmoil experienced in different corners of the world.

To maintain this business continuity, it is highly critical that enterprises manage supplier risk throughout the supplier lifecycle.

Keep two things in mind for Enterprise supplier risk management.

- First, the performance and evaluation of suppliers is not a one-time activity.

- Second, while supplier relationships are important, continuously assessing risk on multiple risk factors is critical too.

Let’s look at what entails end to end enterprise supplier risk management.

Why is Supplier Risk Management Important?

Thinking about supplier risk management process is like thinking of a chain, if any one link breaks the whole chain breaks. Supplier chain is similar, if a supplier goes bankrupt your supply chain comes to a halt and creates major business impact.

In 2021, a fire at a Japan’s semiconductor factory cause shortage of semiconductors globally. This shortage caused a very high impact on various industries such as automotive, consumer electronics, and appliances. Many factories started on demand production, and some shut down their factories due to this shortage.

Risk from suppliers is high as it’s an unknown territory and a space that is not in direct control or most enterprises. But if done right, enhanced supplier risk management can enable the procurement teams to create an impact on companies’ continuous success.

Creating resilience and tackling unpredictable risks, changing laws, supplier performance, financial risk, cybersecurity etc. can give enterprises competitive advantage.

1. Protection from financial losses

If supplier is not continuously tracked, often red flags can get ignored and that can cause major impact on business. It’s like being in a toxic relationship that’s going to harm you. So, building protection mechanisms are important.

Supplier risk management can help to identify and mitigate these risks not just during supplier onboarding but throughout the supplier’s lifecycle. This helps in reducing the likelihood of financial losses.

2. Adhering to compliance and regulations

More often than not a robust supplier risk management falls under regulatory bodies. For example, GDPR (General Data Protection Regulation) states that enterprises must have adequate controls to protect PII data of their customers and employees. Supply risk management enables necessary compliance with regulatory requirements.

3. Safeguarding company reputation

Getting involved in ethical breaches can cause a whole lot of ruckuses, and a PR nightmare for enterprises. It reflects poorly to the customers, investors, and rest of the world. Supplier risk management enables organizations to identify and avoid working with suppliers that pose reputational risk.

4. Ensuring quality goods and services

A track record of suppliers who have consistently delivered good quality goods and services within reliable timelines helps enterprises ensure great quality. Supplier risk management does the heavy lifting in maintaining these records of supplier performance and creating a resilient supply chain.

Supplier risk management strategy

Now that we have established the importance of supplier risk management solutions, we already know that enterprise’s risk management strategy isn’t complete without an effective supplier risk management strategy.

Validating this in 2021 Gartner Supply Chain Risk and Resilience Survey showed at least 75% of supply chain companies have either implemented or are implementing a risk management organization.

The question is how do you start doing it? Here’s a very quick AMM framework to follow.

ASSESS | MONITOR | CONTROL

Step 1 – Assessing Supplier Risk Management Strategy

This starts by self evaluation, do you have clear visibility of all suppliers in your supply chain? And are you regularly monitoring the risks posed by them?

If the answer is yes, you have already got a head start. But if the answer is no, then this is exactly where you start your supplier risk management strategy.

- Assess and identify the critical suppliersIt starts by getting a clear visibility of each supplier in your supply chain. Once you obtain visibility into your supply chain, categorize these suppliers into different segments. These segments could look like – strategic, high-value, or non-critical suppliers.This step-in supplier risk management helps you understand suppliers that can cause highest impact on the business.

- Assess the risk areas with each supplierIdentify potential risks associated with each supplier, now this can be extremely challenging if you are working with thousands of suppliers. Hence it becomes impractical to individually track risks, given these risks can come from multiple sources.

AI for supplier risk management tracking can help get cognitive intelligence to help do this effectively and quickly, supplier risk management tools such as Supplier Risk Management Radar.These tools can ease supplier risk management process for enterprises continuously and consistently.

- Run risk assessmentsRisk assessments are carefully curated surveys for each supplier utilizing KPIs most critical to organization. This is sent to suppliers and once a response is received, a review is conducted by the functional partners. If the reviewer is satisfied, they will provide feedback, if not they will return it before marking it complete.Utilize supplier risk management tools that allow you to track supplier risk management assessment progress from supplier onboarding to supplier lifecycle. You can also checkout the things that enterprises should avoid during risk assessment.

Step 2 – Supplier Risk Monitoring

Monitoring supplier on continuous basis is important to maintain quality and avoid end moment risks.

- Critical risk monitoringPost running risk assessment, each supplier is assigned an assessment score. These assessment scores are against each of the categories of risk, ESG, Information Security etc. This data can further be enhanced by assigning red, amber, green status to understand highest to lowest risk status.

- Risk based supplier segmentation strategyCreating visibility of different suppliers with respect to risk, helps in creating specific cohorts. 360 degree risk evaluation helps in creating automated alerts and identifying the risk trends.This should not only rely on data provided by supplier but also utilize information available from third parties and secondary sources. Hence integration of software with sources such as Ecovadis, D&B becomes an additional advantage.AI powered supplier risk management software can create a highly efficient process. One view dashboard to get alerts, impacted suppliers across globe, spend volume on each of those suppliers, and severity filters makes supplier risk management easy.

Step 3 – Manage and Mitigate the Risk

- Run performance eventsDefine clear and measurable performance metrics that align with your supplier’s role and responsibilities. These metrics can include on-time delivery, product quality, lead times, and customer service responsiveness.Establish a consistent schedule for performance reviews and evaluations. These can be conducted quarterly, semi-annually, or annually, depending on the criticality of the supplier.

- Develop Supplier risk management program such as SCARSCAR is a formal process used to point and improve the non-conformities or issues related to a supplier’s products or services. When a problem is identified, a SCAR is initiated, outlining the issue, its impact, and the corrective actions required.SCAR involves doing a root cause analysis to determine why the issue occurred. This helps enterprises not to repeat the same mistake with suppliers of concern.Collaborate and get involved with suppliers in joint problem-solving, process improvements, and training if necessary.Ensure that all SCAR-related activities are well-documented, including the initial issue, corrective actions taken, and verification of those actions.

Check out this three-step guide for risk mitigation

Supplier Risk Management Best Practices

Effective supplier risk management is essential for maintaining a resilient and reliable supply chain. Here are key best practices to enhance your supplier risk management efforts:

1. Conduct Comprehensive Risk Assessments

Begin with a thorough assessment of potential risks associated with each supplier. Evaluate factors such as financial stability, operational capacity, compliance with regulations, and geopolitical risks. Utilize tools like risk matrices to categorize and prioritize risks based on their likelihood and impact.

2. Develop Strong Supplier Relationships

Building robust relationships with suppliers can significantly mitigate risks. Engage in open and transparent communication, fostering trust and collaboration. Regularly share information about potential risks and work together to develop contingency plans. Long-term partnerships often result in better risk management and more reliable supply chains.

3. Diversify Your Supplier Base

Relying on a single supplier can be risky. Diversify your supplier base to reduce dependency on any one source. This approach spreads risk and ensures that disruptions from one supplier do not halt your entire supply chain. Consider sourcing from multiple geographical locations to further mitigate regional risks.

4. Implement Continuous Monitoring

Regularly monitor suppliers and the broader market environment to identify emerging risks. Use technology and data analytics to gain real-time insights into supplier performance and potential risks. Early detection of issues allows for proactive risk mitigation.

5. Establish Clear Contracts and Agreements

Clearly defined contracts and agreements are crucial in managing supplier risk. Include specific clauses that address risk-related scenarios, such as penalties for non-compliance, requirements for regular risk assessments, and obligations for transparency. Ensure that contracts are regularly reviewed and updated to reflect changing circumstances.

6. Invest in Supplier Development

Support your suppliers in improving their capabilities and resilience. Offer training, resources, and expertise to help them enhance their processes and manage their risks more effectively. A stronger supplier base contributes to a more resilient supply chain.

By implementing these best practices, organizations can enhance their supplier risk management, ensuring greater supply chain stability and minimizing the impact of disruptions.

Read more: Top 10 Supplier Risk Management Best Practices For Procurement Professionals

Supplier Risk Management Software

All the things above to be done manually pose some great challenges for enterprises, hence, supplier risk management at a large-scale automation with technology comes in handy. Supplier risk management tools help enterprises manage risks effectively as the supplier base grows or business expands into new markets.

Leverage technology to mitigate supplier risk.

These solutions can also help enterprises:

- Get real-time visibility into the supply chainSupplier risk management software enables enterprises to proactively identify and assess potential risks. It automates the process of identifying various types of risks and helps enterprises in easier prioritization to address these risks.

- Customized risk scoringCustomized risk scoring models tailored to your organization’s specific needs and risk tolerance, ensures that risks are assessed in a way that aligns with your business objectives.

- Automated data collection and analysisUsing automation enterprises can easily collate data from multiple sources, with reduced risk of error. Advanced analytics supplier risk management tools that help you understand historical data such as supplier performance data.

- Seamless supplier collaborationSupplier risk management software provides enterprises with easy access to their suppliers. Tracking information around risk assessments, status of workflows, monitoring and development of suppliers is much simpler.

- Predictive risk triggers with AIAI-driven risk analysis enhances the accuracy and predictive capabilities of the software, enabling organizations to proactively address emerging risks and make more informed decisions. This cognitive data driven approach is still rare in supplier risk management software, only a few software tools have built this capability.

ROI of Supplier Risk Management Software

There are some clear returns from investing in a supply chain risk management software.

Cost Savings: Supply chain risk management software can help enterprises lead substantial cost savings by optimizing supplier relationships, reducing procurement costs, and mitigating supply chain risks.

Efficiency Gains: Predictive risk triggers. AI powered risk analysis and streamlined processes improve efficiency, reducing labor costs and freeing up procurement teams to focus on strategic activities.

Risk Mitigation: Effective risk management through software can prevent costly supply chain disruptions, regulatory fines, and reputation damage, directly contributing to ROI.

Read our blog on: Choosing the Right Vendor Risk Management Software

Zycus Supplier Management Software

Discover how Zycus can help you unlock the full potential with effective supplier management software. Our solution is designed to ease supplier management, streamline operations, and improve supply chain resilience, thereby driving cost efficiency. Leverage Zycus’ supply management solution to get the most out of your supplier relationships and take your business to the next level.

Zycus’ supplier management solution offers a comprehensive set of features that help you mitigate supplier risk, improve supplier performance, and drive innovation throughout your supply chain.

- Zycus Supplier Network(ZSN) – End-to-End Supplier Management Portal

- iSupplier – Supplier Information Management

- iRisk – 360° Supplier Performance and Risk Management

FAQs

Q1. What is supplier risk management?

Supplier risk management is the process of identifying, assessing, monitoring, and mitigating risks associated with suppliers to ensure supply chain continuity and business resilience.

Q2. Why is supplier risk management important for enterprises?

It helps organizations prevent supply disruptions, financial losses, compliance failures, and reputational damage caused by supplier-related risks.

Q3. What types of risks are addressed in supplier risk management?

Common risks include financial instability, operational disruptions, geopolitical events, regulatory non-compliance, ESG issues, cybersecurity threats, and supplier performance risks.

Q4. How is supplier risk management different from enterprise supplier risk management?

Enterprise supplier risk management focuses on continuous, organization-wide monitoring of supplier risk using internal data, third-party intelligence, and predictive analytics.

Q5. Is supplier risk management a one-time activity?

No. Supplier risk management is an ongoing process that requires continuous monitoring throughout the supplier lifecycle to identify emerging risks early.

Q6. What are the key steps in a supplier risk management strategy?

A typical strategy follows three steps: assess supplier risks, continuously monitor risk indicators, and manage or mitigate risks through corrective actions and contingency planning.

Q7. How does technology improve supplier risk management?

Technology enables real-time risk visibility, automated assessments, AI-driven risk scoring, predictive alerts, and integration with external data sources.

Q8. What are the benefits of supplier risk management software?

It improves risk visibility, speeds up decision-making, reduces manual effort, enhances supplier collaboration, and strengthens compliance and resilience.

Q9. How does supplier risk management support compliance and ESG goals?

It helps organizations track regulatory adherence, ethical sourcing, sustainability metrics, and supplier conduct to meet ESG and legal requirements.

Q10. How does Zycus help with supplier risk management?

Zycus provides AI-powered supplier risk management solutions that enable continuous risk monitoring, predictive insights, performance tracking, and proactive risk mitigation.

Related Reads:

- Top 10 Supplier Risk Management Best Practices For Procurement Professionals

- Riding the Digital Wave: The Evolution of Supplier Risk Management in Procurement

- Proactive vs. Reactive: The Importance of a Supplier Risk Management Plan

- eBook -Unlock the Secrets to Effective Risk Management

- eBook – Discover the 9 Steps to More Effective Supplier Risk Management Process

- Whitepaper – Supplier Risk Management Program Framework: A Comprehensive Approach to Mitigating Supplier Risks

- Webinar – Building Blocks for a Robust Supply Chain: Balancing Supplier Performance and Risk

- Whitepaper – Ensuring Efficient Supplier Risk Management with Supply Chain Transparency

AI for supplier risk management tracking can help get cognitive intelligence to help do this effectively and quickly, supplier risk management tools such as

AI for supplier risk management tracking can help get cognitive intelligence to help do this effectively and quickly, supplier risk management tools such as